製造工程 Process

商品の製造工程

商品が出来上がるまでには以下の工程順となります。

1. 企画

商品企画では、使う人が・どういう時に・どんな風に使うのかを考え、それに相応しい機能やデザインはもちろん、価格設定にも配慮した商品を企画し、ビジョンを構築します。

2. 成形

弊社商品はプラスチックが主流です。

最近は電子レンジや食器洗い乾燥機に対応し、においが比較的少ないPETとABS樹脂の複合成形材料の利用がほとんどですが、環境への負荷が少ないプラスチックと天然素材を掛け合わせた「バイオマスプラスチック」を利用した商品も増えています。

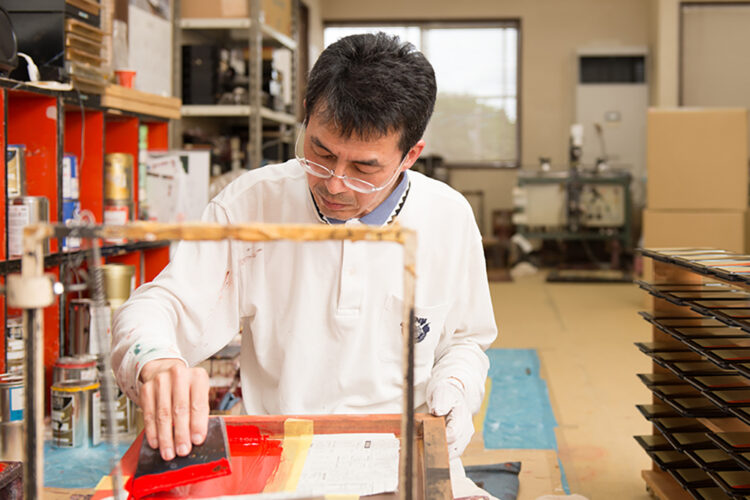

3. 塗装

弊社商品は基本的に塗装(塗り)が施されています。

塗師(ぬし)とよばれる職人によって、ひとつひとつ丁寧な塗装をして仕上げます。

職人の技術により、木目調からメタリックな塗装までバリエーション豊かな商品を展開できるため、多品種小ロットの販売が可能になります。

また、近年は「抗菌」や「抗ウイルス」、汚れが落ちやすい「汚染防止」などの様々な効果のある塗料が使用できるため、より付加価値のある機能的な商品が生産できます。

4. 蒔絵

蒔絵師(まきえし)とよばれる職人によって、商品に蒔絵(印刷)を加える事ができます。

蒔絵はシルクスクリーン印刷を中心に行っておりますが、金粉や色粉などを用いた色のグラデーションや、絵を盛り上げて表現する盛絵など、手作業独特の多彩な表現も可能です。

また、インクジェットプリンターを用いた、複雑で多色なイラストなどの印刷も可能です。

5. 検品・箱詰め

仕上がった商品をひとつひとつ検品し、梱包して最終的な商品が完成します。

昨今、商品本体の品質だけでなく、外装など様々な部分の品質も要求されており、品質に関する要求は日々高まっております。

そのニーズに応えられるように、日々製造工程の見直しや改善を図り、よりよい「ものづくり」ができるように努力しております。